Practice Free MB-330 Exam Online Questions

A company manufactures and sells speaker boxes. The speaker boxes can be silver or black with a basic or upgraded wiring harness assembly.

The speaker box must be created in the item master so that the variables for colors and harness type can be assigned at order entry.

You need to create a new item that supports multiple variables.

What should you do?

- A . Create a new product. Select predefined variant as the configuration technology.

- B . Create a new product master. Select constraint-based configuration as the configuration technology.

- C . Create a new product. Select constraint-based configuration as the configuration technology.

- D . Create a new product master. Select predefined variant as the configuration technology.

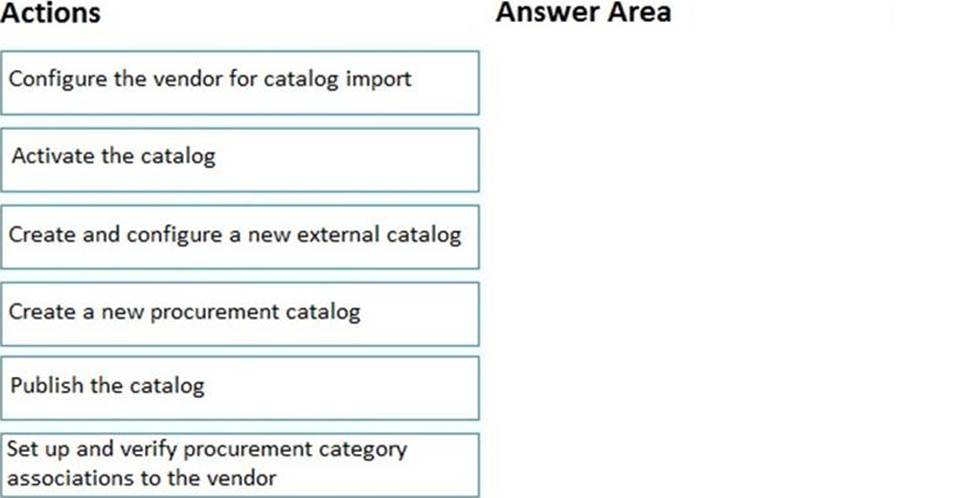

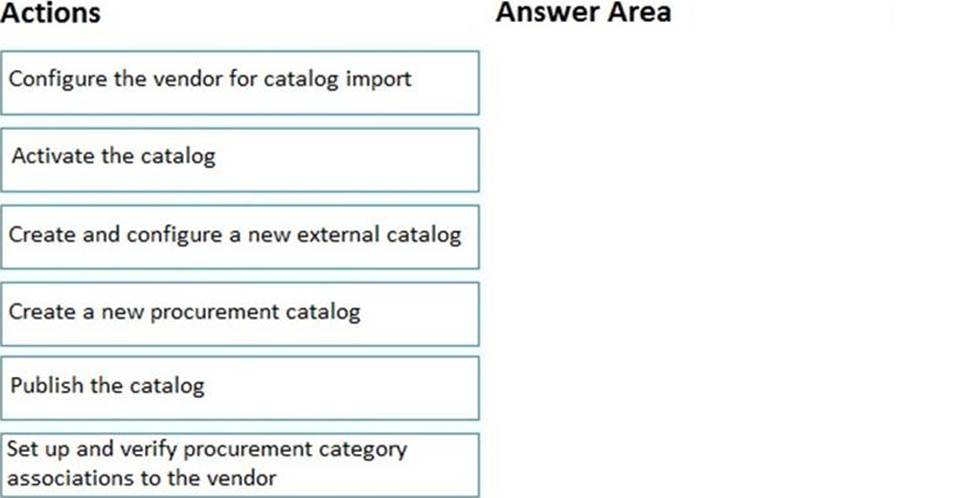

DRAG DROP

A company wants to expand their purchasing power by enhancing their current procurement catalog in Dynamics 365 for Finance and Operations.

The company wants to redirect to external websites to help build their purchase requisitions.

You need to set up an external catalog.

Which three actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

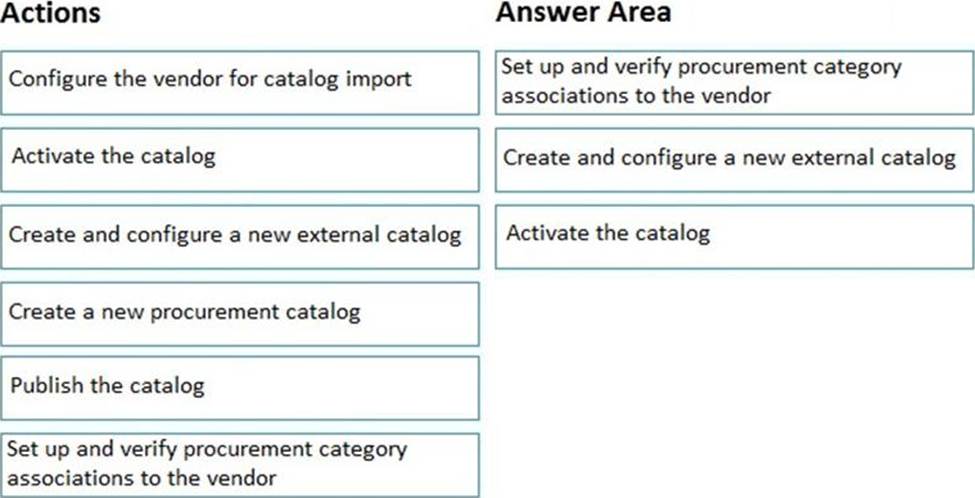

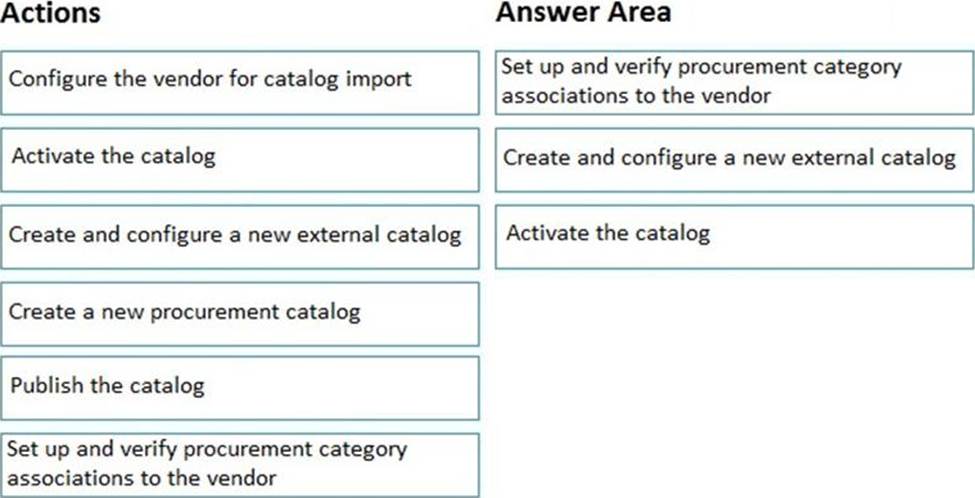

DRAG DROP

A company wants to expand their purchasing power by enhancing their current procurement catalog in Dynamics 365 for Finance and Operations.

The company wants to redirect to external websites to help build their purchase requisitions.

You need to set up an external catalog.

Which three actions should you perform in sequence? To answer, move the appropriate actions from the list of actions to the answer area and arrange them in the correct order.

A company is configuring per diem rules in Dynamics 365 Finance as part of its expense management.

The company requires the per diem rate to be automatically reduced by different percentages when specific meals, such as breakfast or dinner, are provided each day to the employee during travel.

You need to set up the per diem rules.

Which configuration should you complete?

- A . Select Meal type per trip and enter reduction percentages for each meal.

- B . Ignore the allowance rate for meal reduction.

- C . Select Meal type per day and enter reduction percentages for each meal.

- D . Select Number of meals per day and default values for reduction percentages for each meal.

C

Explanation:

Comprehensive and Detailed Explanation From Exact Extract:

In Dynamics 365 Finance, when configuring per diem rules for expense management, the system supports reducing the per diem rate based on specific meals provided during travel (e.g., breakfast, lunch, dinner). This reduction is applied on a per day basis, not per trip.

Meal type per day configuration allows you to specify reduction percentages for each meal type (breakfast, lunch, dinner) for each day of travel.

This setup automatically adjusts the per diem amount when an employee receives one or more meals, preventing overpayment of per diem allowances.

Reference: Microsoft Docs – Per diem rules and meal reduction

"You can configure per diem rules to reduce the daily allowance based on the types of meals provided to the employee on each travel day."

Why other options are incorrect:

A (Meal type per trip): Meal reductions are not applied on a per-trip basis but rather on each travel day to ensure daily accuracy.

B (Ignore allowance rate for meal reduction): Ignoring the allowance rate negates the requirement to reduce per diem automatically.

D (Number of meals per day with default values): While number of meals can be tracked, the reduction is specifically based on meal types with individual reduction percentages, not just the count of meals.

You need to address the inventory costing requirements.

What are two possible ways to achieve the goal? Each answer represents a complete solution. NOTE: Each correct selection is worth one point.

- A . Use FIFO with marking.

- B . Create purchase orders from sales orders.

- C . Set up commodity pricing.

- D . Create a costing version.

- E . Set up a costing sheet.

You use Dynamics 365 Supply Chain Management to manage inventory.

Multiple forms are currently required to make insights against inventory supply metrics for an item actionable.

You need to use the supply schedule form to streamline operations.

Which three objects can you use to achieve the goal? Each correct answer presents a complete solution. NOTE: Each correct selection is worth one point.

- A . Transfer orders

- B . Safety stock journals

- C . Scheduled Kanban

- D . Production orders

- E . Demand forecast

A company employee is in charge of warehouse operations and controlling inventory adjustments through journals.

The employee needs to add inventory for samples at a specific cost. The samples were shipped by a vendor without a purchase order. The employee needs to be sure that the inventory value goes to a ledger account so that the value of the samples is not mixed in with another inventory value.

You need to ensure that the employee is able to correctly add the inventory.

What should you do?

- A . Create a movement journal, add the cost, and specify the offset ledger account on the line.

- B . Create an adjustment journal, add the cost, and specify the offset ledger account on the line.

- C . Create an arrival journal, add the cost, and specify the offset ledger account on the line.

- D . Create a transfer journal, transfer to a different warehouse, and then adjust the cost.

A

Explanation:

Reference: https://docs.microsoft.com/en-us/dynamics365/unified-operations/supply-chain/inventory/inventory-journals

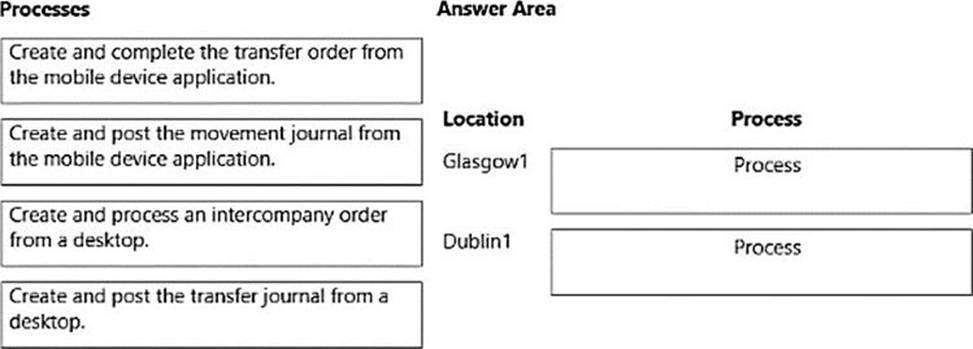

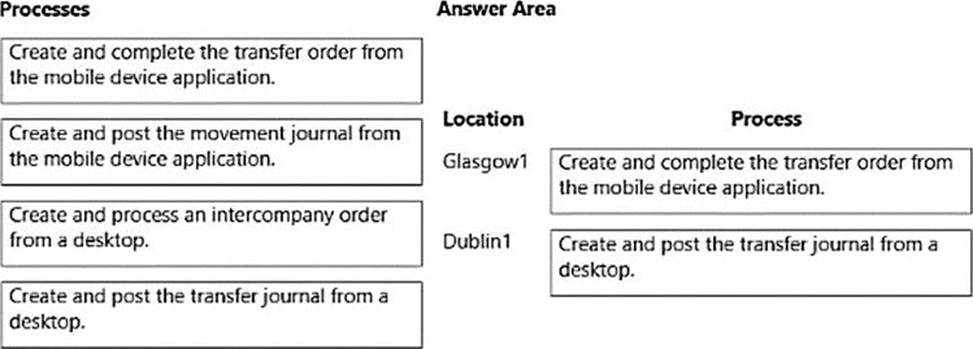

DRAG DROP

You must meet the requirement for WarehouseWorker1.

Which process should you use? To answer, drag the appropriate processes to the correct locations. Each process may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content. NOTE: Each correct selection is worth one point.

A company is implementing sales order functionality in Dynamics 365 Supply Chain Management. The company has a business requirement to fulfill sales orders by using direct delivery. You need to enter a direct delivery sales order so that a purchase order is automatically created.

What should you do after you enter the sales order and lines?

- A . Change the order type to journal and manually enter a PO for the sales order line items on the sales order header.

- B . Select automatic and confirm the sales order on the line level setup tab in the reservation field.

- C . Change the site to direct delivery and confirm the sales order.

- D . Change the delivery type on the sales order line to direct delivery and select save.

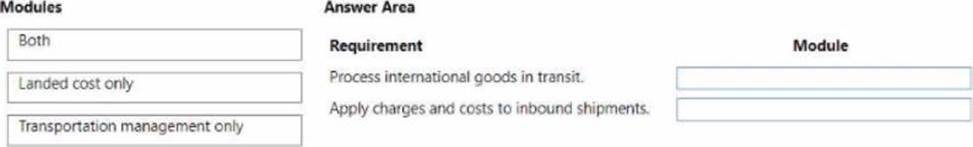

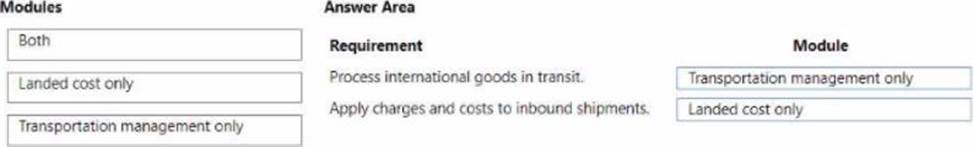

DRAG DROP

A company is implementing Dynamics 365 Supply Chain Management The company has vendor agreements with domestic and international companies.

A production controller requires the ability to process the goods in transit to the company from international vendors.

Charges and costs require the following setup:

• applied to domestic and international inbound shipments

• separate purchase orders

The company will not create inbound Wads automatically

You need to determine which module to configure to meet the requirement for inbound shipments.

Which module should you use? To answer, drag the appropriate modules to the correct requirements. Each module may be used once, more than once, or not at all. You may need to drag the split bar between panes or scroll to view content. NOTE: Each correct selection is worth one point.